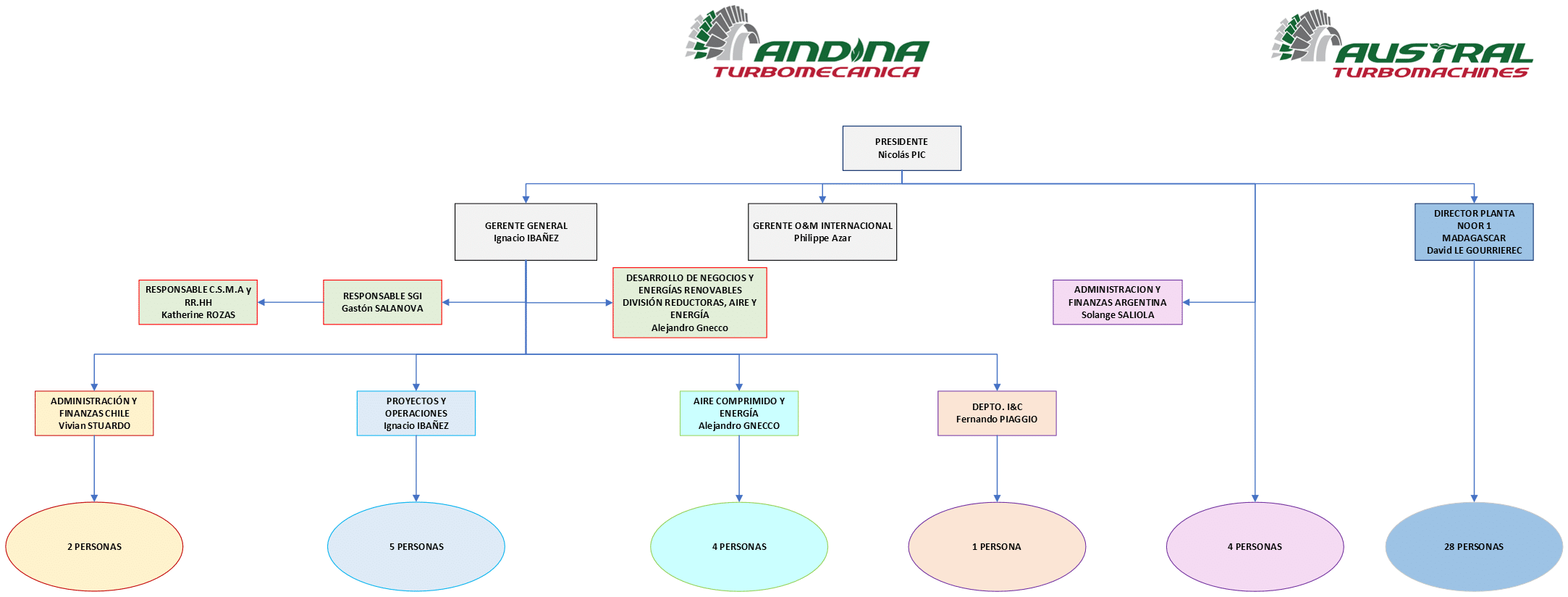

Our Company Andina Turbomecanica

Andina Turbomecánica was created at the beginning of 2010 by a team with a lot of experience in the power generation industry in order to contribute to the development of a clean, economical and reliable generation of energy in a sustainable development framework for our continent

Social Commitment

Andina Turbomecánica voluntarily made the decision to apply a 40-hour work week to all its staff.

Our Team

An efficient, competent, supportive and flexible team..

Mission

The main purpose of the company is to provide the best service to power generation companies, essentially in Latin America, providing them with competitive prices for all special and common spare parts they need, always committing to deliver premium quality products (OEM), and taking advantage of the proximity that confers our location on the continent

Commitment

Within the power generation sustainable development framework, Andina Turbomecánica established a voluntary commitment to power plants socio-economic environment. Whenever conditions allow, we use local resources for our interventions: personnel, conventional supplies, auxiliary services, always looking at a fair distribution of the associated benefits.

Program

Today, energy cannot be generated without a deep commitment to the environment. Therefore, Andina Turbomecánica developed an important program that includes:

• Supply of OEM spare parts for gas turbines, especially GE FR5, FR6 & FR9E.

• Exclusive representative of Flender Graffenstaden, spare parts and services for gearboxes.

• We provide specialized maintenance services for these gas turbines.

• Supply of OEM spare parts for slow and semi-fast reciprocating engines (Sulzer ZA40S, Wärtsilä, etc …) – DUAP injectors.

• Advisory services for O&M and integral O&M.

• Turnkey development and procurement of an emission reduction system for any GT in OCGT without overloading Hot Gas Path and with a cost up to 4 or 5 times less than a traditional DLN system.

• Upgrade of gas turbine control systems and other generation equipment.

Our team is composed by a group of professionals from different areas and disciplines that contribute to the common goal of moving together to grow personally and professionally together with the company in order to position itself as a leading company in the market.

We have more than 35 years of experience with Electricity of France, Water and Energy, Stewart Stevenson… in Operation and Maintenance, construction and commissioning. Thermoelectric power plants with fossil fuel (gas, coal, diesel) and nuclear, combined cycles, open cycle gas turbines, systems operation and maintenance in electrical island mode, high power diesel engines and gas turbines.

- Planning, organization, execution and supervision of scheduled and forced gas turbines maintenance work.

- Assistance for electrical, mechanical, quality management, environment, safety and work planning.

- Staff training for operation of gas turbines and equipment associated with thermoelectric plants.

- Evaluation, implementation, commissioning, commercial and technical administration of open cycle, combined cycle and cogeneration thermoelectric plants of national companies.

- Preparation and supervision of operation and planned maintenance execution for Industrial and aero-derived turbines: GE Fr 5, Fr 6 and Fr9, LM2500, LM6000… Pratt & Whitney FT4 and FT8, Wärtsilä, Cummins, Caterpillar, Sulzer… engines and associated systems.

- Advice on power plants commercial management, relationship with the system

- Voltage regulators controls & adjustments, excitation and synchronization systems.

- Short circuit electrical tests, instrumentation and controls for turbines and alternators.

- Preparation and execution of maintenance of GE units Fr 5, Fr 6 and Fr9, LM2500, LM6000 …

- Mantenimiento programado y ajustes en sistemas de control Speedtronic Mark II, IV, V, VI, Allen Bradley, Siemens…

- Determinación de niveles de ajuste de protecciones eléctricas de generador, transformador de unidad y auxiliares.

- Control of balancing and assembly of turbine rotors.

- Quality control of the components during turbines hot gas path inspection (combustion chambers, transition pieces, 1st and 2nd stage nozzles, 1st and 2nd stage buckets).

- Scheduled maintenance of gas turbines and auxiliary systems.

- Analysis and diagnostic imaging (Borescope).

- Diagnosis by non-destructive tests.

Sustainable development

Within the framework of sustainable development, Andina Turbomecanica always committed to the community, has been present in this pandemic by contributing with community pots